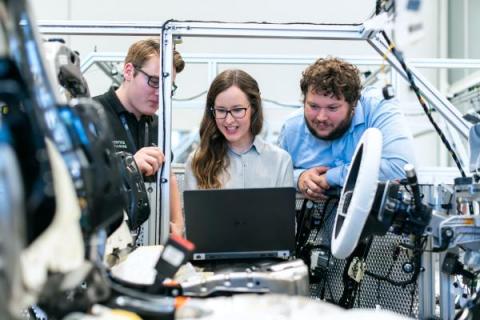

How Manufacturing Software Solutions Offer Productivity, Profitability, and Expansion

In today's fast-paced industrial landscape, businesses constantly seek ways to enhance efficiency and achieve success. Through software tools tailored for manufacturing companies, they are revolutionizing operations to boost productivity, foster profitability, and facilitate expansion. These technological strides offer companies an advantage, enabling them to adapt to evolving market demands.